The Anvil Viewer provides import capability for popular CAD/CAM file formats, letting you view, print & plot.Īnvil Viewer reads the most popular formats including, ANVIL EXPRESS (.AXP), ANVIL-5000 (.PRT. WHY? Cause you can? I think it be best, if your just wanting you a anvil to buy a used or new anvil, and alot less trouble.ANVIL VIEWER - Multi-format View and Print programĭo you have designers working with various CAD/CAM file formats? Perhaps you have engineers or shop staff that only need to view data.

Why not make an ornate bridge anvil or something akin, rather then just make something that looks like the commercial equivalent only costing much more to fabricate. Something that can't be found or mates with a very specific purpose.

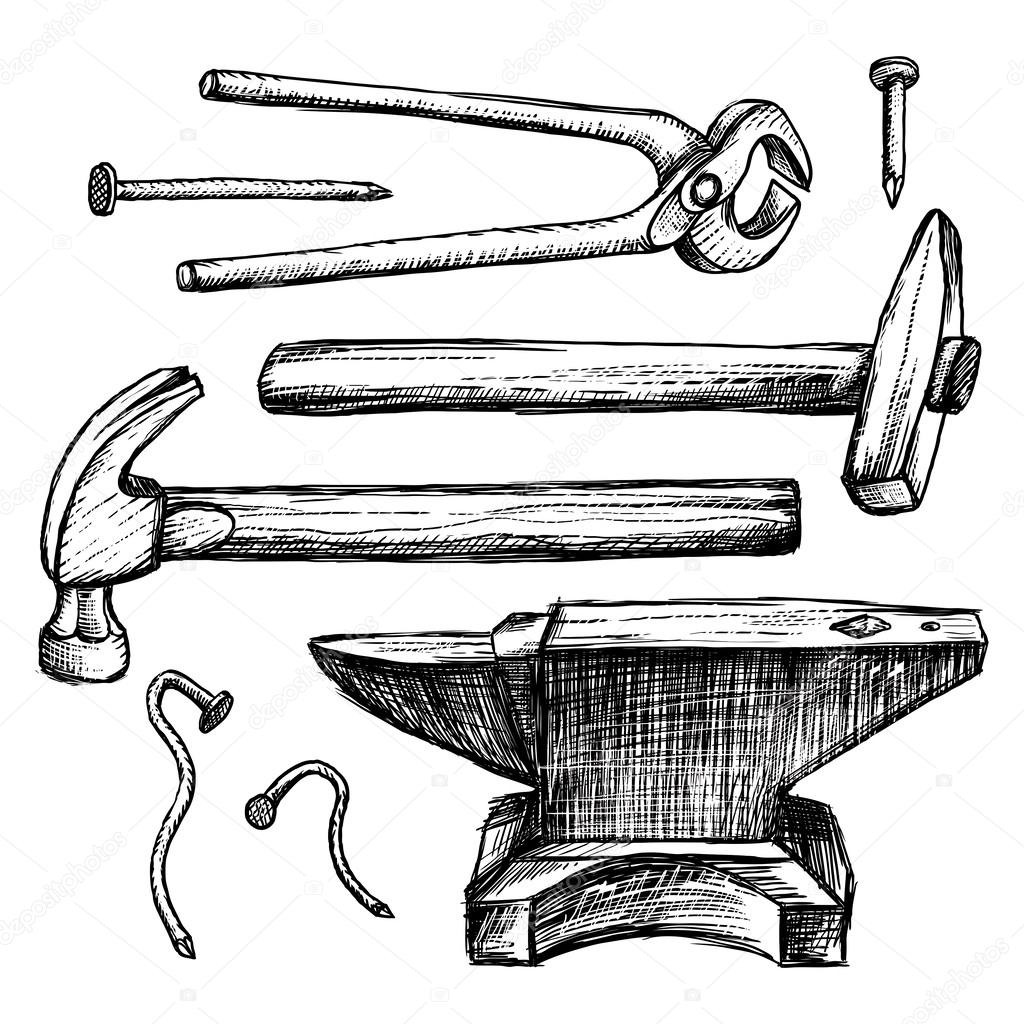

If your going to weld/fab/temper your own anvil why not make something extremely exotic. My 450# anvil came 2300miles for only about $300.00 so unless you just have to build your own i'd check the shipping methods out fully before you give up. You can always get your anvil to come on a shipping container on a freighter and its not that expensive. why god, why? lol You could have a manufactured anvil shipped to the far side of the universe for what it will cost you to make your own of equivalent quality and weight. Seems like a great learning process and a fascinating engineering and scientific challenge, but outside of that. I will probably sell it on ebay.Īm looking forwards to seeing those pic,s of your anvil Dave, can we see progress pic,s And I can,t help myself as I,ve always got projects on the boil. I will try to source scrap only and my overheads are very low. These are some prices we pay in OZ, so I have to complete with these sorts of pricesĪustralian Anvil O,dwyer 88lbs = from $614usd = $767aud Some might think "twin horn fabricated anvil, heavens forbid" (and maybe not) I,ll try and keep it simple. before, so I don,t know how well it would sell, so I,ll stick with a known pattern. Yes, good point Thomas, I will make myself a real flash twin horn, side shelf, jobbing block, special holes everywhere, all bells and whistles later, but for now I want to made a commerical unit to sell. Why do a custom piece and then want it to look just like a common commercial item? The "ideal" anvil is the one that best supports *your* methods of work and items you generally make! Look at some of the new ones with the graduated punching holes in them. I doubt that you will find them but many sites give the dimensions of their anvils and from a down loaded picture it is possible to scale the dimensions you don't have fairly closely.Īll you need for that is any grapic program, a printer and a pair of dividers. Struck on end it is as solid as an anvil twice its 77 lb's.Īs for Patterns. I have an 11x5.5" block that I use to supplement my Russian ASO. My real suggestion is to by a section 6" or 7" square 4140 billet and cut/grind it to the shape you want. Making an anvil like to ones that are manufactured is difficult to say the least. I think you might find it cheaper to buy a used anvil or even a new one. Then take the pattern to a steel foundry and ask them to make a casting in 4140 steel.įrom there find a heat treater with equipment for heat treating steel and ask them to treat it.Īfter that find a machinest with a good surface grinder to do the face for you. I would suggest that you borrow an anvil that you like and make a wooden pattern to match it.

0 kommentar(er)

0 kommentar(er)